Examples for such metals are titanium, tantalum, niobium, and molybdenum. They are all characterized by a very high melting point. Tungsten, for example, melts at 3410°C (6170°F). This is more than double that of iron and ten times that of lead. They are also very reactive to many nonmetals. Therefore, in most cases, the only way to melt these metals in a cost-efficient way is under vacuum conditions and with powerful heat sources.

Why do these metals have to be melted?

This melting is necessary to create metals with the desired composition, structure, and purity for the following processing steps. In some cases, it might be necessary to repeat that process two or three times, for instance for applications in the aerospace industry.

Electron beam guns are excellent heat sources for this due to their power density and ease of use. They can be easily combined in various arrangements. This enables a special melting furnace configuration such as the one used for the refining of titanium: Electron beam cold hearth refining.

For this method, the titanium, which has been melted using a high-power electron beam gun, is not poured directly into a casting mold but first into a water-cooled copper crucible. The contaminants settle in the crucible so that the purified molten titanium can be poured into the mold.

It is possible to use additional electron beam guns in these furnaces to keep the molten titanium liquid. There is no comparable method that could compete with electron beam melting in creating titanium in this high quality in a cost-efficient way.

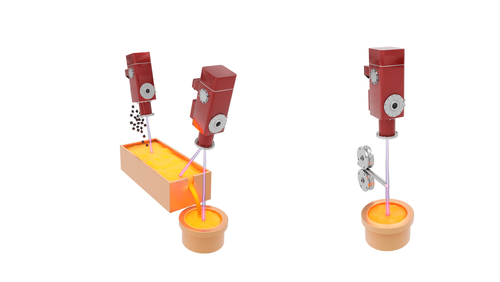

Drip melting is another, slightly older, method that is used for melting such metals. The feedstock of the refractory metal (niobium, tantalum or molybdenum), which in most cases is fed horizontally, is melted at its end using an electron beam. The molten material drips into a water-cooled mold. The crystallization process is controlled by another electron beam that is directed on the surface of the mold.

Summing up, we can say that the use of reliable high-power electron beam technology enabled the development of melting methods and furnaces for producing refractory metals and their alloys cost-efficiently in the required quality.

VON ARDENNE has been working with electron beam technology for more than 60 years and has developed the most powerful electron beam gun in the world with a power of 800 kilowatts. VON ARDENNE electron beam systems can be used for melting, refining, evaporation or heat treatment. This video shows two examples of evaporation and melting.