If you are using magnetron sputtering in your manufacturing, we can provide high-quality components needed for creating excellent coating results, no matter if you are using our equipment or third-party systems. Among them are end blocks and magnet bars that are needed for magnetron sputter sources with rotatable targets.

End Blocks

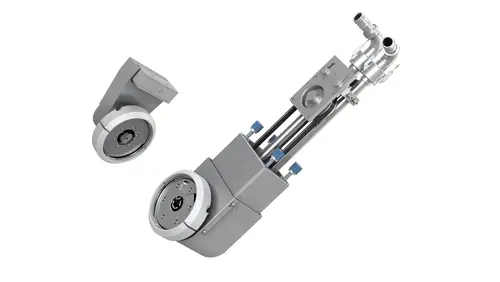

In simple terms, end blocks are components holding the target cylinders in place, rotate them and supply them with energy and cooling water. As they are constantly in operation, they need to be very reliable. To guarantee that, they need to be serviced after a certain time. It is vital that this maintenance is both easy to do and fast as it holds up the entire coating process. It is also preferable that the maintenance intervals are as long as possible.

Our latest X-Series End Blocks are a very good option for customers looking for such qualities. The X-Series is available for upgrades and retrofits for all coating systems, regardless of the manufacturer, and covers a wide range of specifications.

The XC-S End Block is a compact, internal drop-in end block for low- to medium-power sputter systems. Typical applications for this type of end block are architectural glass, photovoltaics, web and display coating and coatings for automotive applications. Furthermore, this end block is easy to maintain and always up to date in terms of seal systems and current transmission.

The new X-Series End Block XC-L is a drop-in end block for mid- to high-power applications such as architectural glass, thin-film photovoltaics, anti-reflective or TCO coatings.

Efficient Wear & Spare Part Concept

Due to the modular setup of these end blocks, the easy accessibility and robust design, only a small number of wear and spare parts must be handled:

- Water and vacuum sealing cartridges for regular service

- Brushes and sealings for advanced service

- Carbon brush exchange can be done individually

- For regular and advanced service, the end block remains installed, no

need for additional end block maintenance areas near production tools - Bearings and further critical parts designed as permanent or “never

needs maintenance” - Seal counter surface and sealing designed as plug and play: interchangeable parts to keep seal systems always up to date

Magnet Bars

Magnet bars are components belonging to rotatable magnetrons and are located inside the rotary target cylinder. They are needed to create and adjust the magnetic field and thereby influence the coating process. In order to enable that, they consist of many Individual magnets.

VON ARDENNE magnet bars are the state of the art in technology. We have installed more than 2000 magnet bars in all fields of coating application. In the development of our magnet bars, we focus on target erosion, layer uniformity, process stability and application-depending field strengths. They are available in a wide range of strengths and lengths and are inspected in our in-house facilities for quality control.

Best Performance & Quality Control on the Market

- Most homogeneous field uniformity in the market with up to 3 x better magnetic field uniformity

- Smaller redeposition zone leading to less arcing and less nodules

- Straight targets instead of dog bone targets, resulting in a cost benefit

- In-house quality control of magnets - only magnets meeting very

demanding specifications are used for assembly of magnetic systems - Our magnetic systems are assembled by skilled workers.

- High sensitivity magnetic measurement during assembly [11 sensor

simultaneous measurement for fast and complete 2D magnetic field

scan] - Re-assembly of magnetic systems if needed, until uniformity spec is

fulfilled

Conclusion

VON ARDENNE equipment is used in over 50 countries. We have established an installed base of hundreds of coating systems worldwide, ranging from small tools to equipment for large-area coating applications. Every day, our customers are facing the challenge of staying in a leading position. And we strive support them with high-quality equipment and components, technology expertise and local service. Customers in China can rely on our strong network of service locations and our manufacturing facility.

Our mission is to create value by bringing our industry leading technology and process experience to our customers. We want to achieve that by offering state-of-the-art hardware solutions with best-in-class performance specifications and reliability.

Furthermore, we offer advanced process control hardware and software solutions to control processes of single sources or in complex layer stacks settings. It is our aim to deliver a guaranteed process result according to your specifications and timeline. And we are confident that we can offer you what you are looking for in a supplier.

If you would like to know more, please contact Ronny Borchel (borchel.ronny@vonardenne.biz) or go to this page.