Dresden, 23 September 2022

The World Conference on Photovoltaic Energy Conversion (WCPEC) combines the world's most important PV conferences with the European PV Solar Energy Conference (EU PVSEC), the Photovoltaic Specialists Conference (IEEE PVSC) and the International PV Science and Engineering Conference (PVSEC). Thus, it provides the ideal platform for international exchange.

Highly efficient solar cells thanks to PVD coating

Soon, highly efficient solar cells will be essential to achieve the targeted climate goals and the shift away from fossil energy sources. N-type cell technologies such as TOPCon and heterojunction are the main concepts available for investing in production at gigawatt scale now. Solar cells with more than 24 percent or over 25 percent efficiency are already on the market. And the potential is not yet exhausted: the next leap to 28 - 30 percent efficiency is expected to be achieved in a few years with tandem technologies. This is a combination of two stacked solar cells for higher efficiencies in mass production.

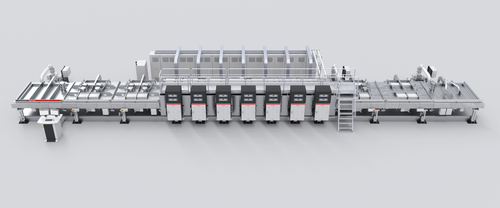

The potential of the three technologies can only be leveraged with PVD coatings1. Thus, both heterojunction and TOPCon technology have already been able to challenge the previous standard (PERC cells) for significant market shares. A significant contribution to this has been made by the mechanical engineering company VON ARDENNE, which has already placed coating systems with an annual production capacity of 14GW on the market.

VON ARDENNE also has a pioneering role in tandem technologies: As one of the world's leading companies in vacuum coating technology and a specialist in scaling, the company is working with its partners on rapidly transferring this technology from the development and pilot stage to highvolume production for gigawatt factories.

Now, VON ARDENNE is presenting the latest results of its development work on heterojunction, TOPCon and tandem solar cells at WCPEC-8 in Milan.

1 PVD (physical vapor deposition) describes a variety of vacuum deposition methods, e.g. sputtering or evaporation

__________

Einladung zu Vorträgen und Präsentationen

Suchen Sie nach Möglichkeiten, die Effizienz Ihrer Produkte im Gigawattbereich zu steigern? Wollen Sie die neuesten Entwicklungen in der Solarzellen- und Modulherstellung kennenlernen?

Auf der Veranstaltung stellen wir fortschrittliche Beschichtungsanlagen für n-Type- und Dünnschicht- Solartechnologien vor und zeigen, wie wir Sie bei der Steigerung der Solareffizienz unterstützen können.

Wir freuen uns auf Ihren Besuch uns an unserem Stand: A8/MiCo North

Sie sind ebenso herzlich eingeladen, unsere Posterpräsentation, Vorträge und Beiträge in Diskussionsrunden zu besuchen:

Monday, 26 September 2022

Visual Presentation, 2AV.1.39

Sputtering of NiOx for HTL in Perovskite Tandem or Single Junction Applications

- 13:30 - 15:00 Perovskite Photovoltaics

- René Köhler (Senior Engineer Technology)

- Poster Area (Silver

Wednesday, 28 September 2022

Roundtable Discussion:

Global challenges for PV Manufacturing and Deployment at an annual Terawatt Level

- 13:30 - 15:00

- Dr. Sebastian Gatz (Vice President Crystalline Photovoltaics)

- Industry Forum (Exhibition Area)

Vortrag:

PVD systems on a GW scale, today & tomorrow

- 4:15 p.m.

- Dr. Sebastian Gatz (Vice President Crystalline Photovoltaics)

- Industry Forum (Exhibition Area)

Thursday, 29 September 2022

Oral Presentation 1DO.12.4:

Potential of Sputtered AZO Layers for the Industrial Manufacturing of Hetero Junction Solar Cells (in cooperation with HZB and Fraunhofer ISE)

- 11:15 Silicon Manufacturing and Material Issues

- Dr. Eric Schneiderlöchner (Director Crystalline Photovoltaics)

- Auditorium Blue 2

Visual presentation, 1DV.4.40:

Single Sided High Throughput Sputter Process Technology for In-Situ Doped n-Type Amorphous Silicon Layers for High Efficiency TOPCon Solar Cells (in cooperation with ISC Konstanz and Fraunhofer ISE)

- 3:15 - 4:45 p.m. Characterization & Simulation of solar cells

- Dr. Eric Schneiderlöchner (Director Crystalline Photovoltaics)

- Poster Area (Silver)

__________

Contact

Date

26 - 23 September 2022

Booth

A8 / MiCo North

Contact

Ingo Bauer

Tel.: +49 351 2637 9000

Fax: +49 351 2637 308

E-Mail: presse@vonardenne.biz

__________

About VON ARDENNE

VON ARDENNE develops and manufactures systems for the industrial vacuum coating of materials, such as glass, wafers, metal strips or polymer films. Depending on the application, these coatings are one nanometer to a few micrometers thin and give the materials new functional properties. Our customers use these materials to produce high quality products, such as solar cells and solar modules, architectural glass and vehicle glazing, fuel cells, lithium ion batteries or microelectronic components for sensor systems and optics. Systems and components provided by VON ARDENNE make an important contribution to protecting our environment. They are crucial when producing products that help to consume less energy or that generate energy from renewable resources.

With more than 60 years of experience in electron beam technology and over 45 years of experience in magnetron sputtering, VON ARDENNE is a pioneer and worldwide leading supplier of systems and technologies in PVD thin-film and vacuum process technology. We offer our customers technologically mature vacuum coating systems, comprehensive expertise and global service. The key components are developed and manufactured in-house at VON ARDENNE.