VON ARDENNE has a long history in evaporation processes. We have provided thermal and electron beam evaporation equipment for many applications. Among them were optical, electronical and wear coatings and coatings for solar thermal energy applications.

More than ten years ago, VON ARDENNE took part in the transformation from point sources in batch systems to linear evaporators in continuously running inline coating systems. This happened especially in the OLED and display industry to achieve cost effective depositions on large areas.

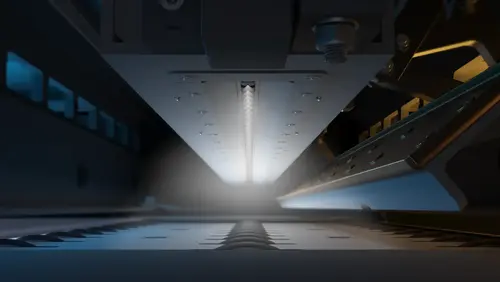

Today, perovskite-based approaches are at the forefront of next-generation photovoltaics. We have adapted and improved our linear evaporators so that they work stably and reliably in this new field of application.

The advantages of vapor phase concepts compared to the solution-based processing of perovskite materials are being discussed in depth within the research community. *

Challenges for large-scale perovskite PV inline manufacturing equipment:

- A coating width of more than 1.000 mm up to 3.000 mm

- A campaign length of at least 10 days

- Industrial-scale dynamic deposition rates to achieve high production throughput

- Conformal deposition on microtextured or textured pyramidal structures for Si-based bottom cells

The technological implementation of the evaporation process can be carried out using either point sources or linear sources. We argue that a point source as a part of a point source arrangement will be geometrically limited in volume, which may limit production time or will need a separate material supply for each point source to extend campaign times.

Beyond that, for point sources, the electrical supplies have to be multiplied by their number and an expensive rate monitor needs to be adapted for each point source in order to ensure the process control loop.

Furthermore, for point sources, an improved thickness uniformity - as a function of source to substrate distance - may limit the material utilization.

The filling level of the point source itself plays an important role in their emission characteristic and the required homogeneous temperature distribution, at least for thermal sensitive materials in order to avoid hot spots, spreading etc., is significantly improved using linear evaporators. Furthermore, linear evaporators are suitable for top-down and bottom-up deposition.

Several of these point source related challenges in high-volume manufacturing systems can be overcome by the introduction of linear evaporation sources.

Benefits of VON ARDENNE linear evaporators:

- Advanced design enables various configurations (geometry & temperature) to meet the evaporation parameters of inorganic/organic based absorber materials as well as organic contact layers, which are required to achieve an effective perovskite cell,

- Achieves industrial relevant dynamic deposition rates

- Offers an excellent coating uniformity independent from coating width and material filling level

- Uses inert (corrosion resistant) material for all parts in contact with the evaporation material

The VON ARDENNE perovskite team invites you to further elaborate on the success factors of linear thermal evaporation. You will find the contact information here.

* Further reading: “Vapor phase deposition of perovskite photovoltaics: short track to commercialization?”