Terawatt age – great opportunities and challenges for Europe

A few weeks ago, the capacity of installed photovoltaics modules has exceeded one terawatt. It took five decades to reach this mark. In a much shorter time – by 2030 to be precise – this capacity now needs to be reached in Europe alone to reach the 1.5 degrees Celsius climate goal.

Building gigawatt factories in Europe is the logical consequence. This will reduce the dependency on fossil fuels such as coal, oil and gas and strengthen the European economy. The initiative to establish a manufacturing capacity of 20 GW by 2025 has been a first step.

PVD is the key – PVD coating crucial for gigawatt manufacturing of high-efficiency solar cells

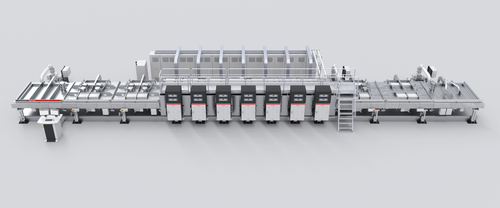

Not only does this ambitious schedule require the fast development of highly efficient cell technologies, but also the reliable transfer of these technologies into mass production scale. PVD* coatings play an essential role for modern cell concepts such as heterojunction, TOPCon or perovskite tandem cells. This applies to thin-film and crystalline photovoltaics alike. VON ARDENNE offers the suitable equipment for the coating requirements of these products. The company sets standards in machine engineering from the development of the laboratory process to pilot lines to high-volume production.

Market leader and Pioneer

VON ARDENNE is the market leader in thin-film photovoltaics having provided coating systems with a manufacturing capacity of more than 22 GW. The German family business holds the same position in the n-type technology market with a provided capacity of 14 GW.

At the Intersolar in Munich, VON ARDENNE will introduce its current product portfolio that will pave the way for customers from research and development to the gigawatt factory.

*PVD (physical vapor deposition) describes a variety of vacuum deposition methods, e.g. sputtering or evaporation.

----------

VON ARDENNE at the Intersolar Europe 2022 in Munich

Booth:

Hall A3 / 454

Contact:

Ingo Bauer

Phone.: +49 351 2637 9000

Fax: +49 351 2637 308

E-Mail: presse@vonardenne.biz

----------

About VON ARDENNE

VON ARDENNE develops and manufactures industrial equipment for vacuum coatings on materials such as glass, wafers, metal strip and polymer films. These coatings give the surfaces new functional properties and can be between one nanometer and a few micrometers thin, depending on the application. Our customers use these materials to make high-quality products such as solar cells and solar modules, architectural and automotive glazing, lithium-ion batteries, fuel cells or components for sensors and optics. Systems and components provided by VON ARDENNE make a valuable contribution to protecting the environment. They are vital for the manufacturing of products that help decrease energy consumption or generate energy from renewable resources.

With more than 60 years of experience in electron beam technology and over 45 years of expertise in magnetron sputtering, VON ARDENNE is a pioneer and worldwide leading provider of PVD thin-film coating equipment and technology and vacuum processing technology. We supply our customers with technologically sophisticated vacuum coating systems, extensive expertise, and global service. The key components are developed and manufactured by VON ARDENNE itself.