Laying the ground

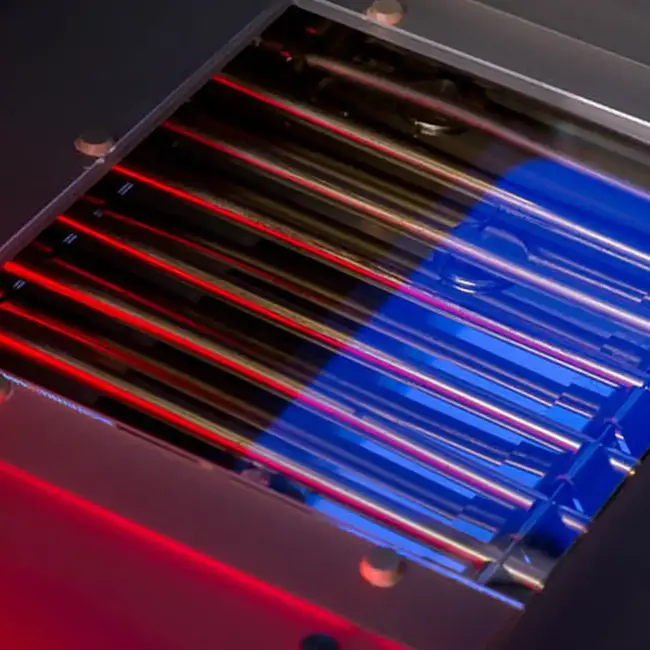

Pretreatment Components

For clean, bond-active substrate surfaces

Surface treatment is often used as a pretreatment to clean, remove or activate the top layer. The pretreatment also serves to form an optimal interface for the layer to be deposited.

This is necessary because the substrate surface is often not well defined. There are also various residues, such as oxides and hydroxides of the substrate material, water, adsorbed gases, and residual impurities from previous processes. These factors can prevent reliable mechanical or functional layer deposition.

Thermal or plasma-based processes are used here to remove residual organic surface impurities or water molecules from the surface in a vacuum, immediately before coating.

Depending on the material or the degree of contamination, the surface coatings evaporate due to the influence of temperature. Or they are literally removed by ion bombardment.

Do you want to learn more? Then click on the individual components or contact us directly.

Components

Engineering

Simulation . Sampling . Layout

Technology & Application Center

Sampling . Development . Scaling

Service

Customer Portal . Spare Parts . Trainings

San Francisco, CA, USA

The Moscone Center

Booth 2261

Tokyo, Japan

Tokyo Big Sight

Shanghai, China

Shanghai New International Expo Center

N1 / 181

Orlando, FL, USA

Orange County Convention Center

Booth 1115

Shanghai, China

National Exhibition and Convention Center

A006