Large-area expertise also for small substrates

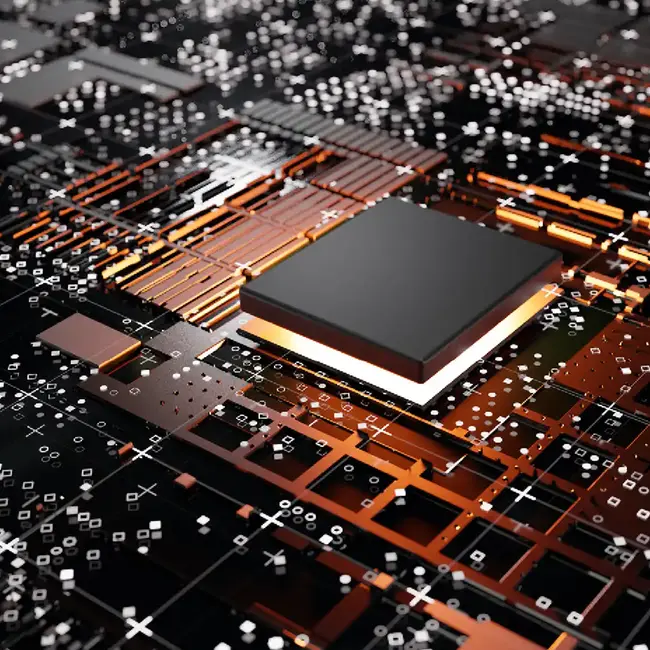

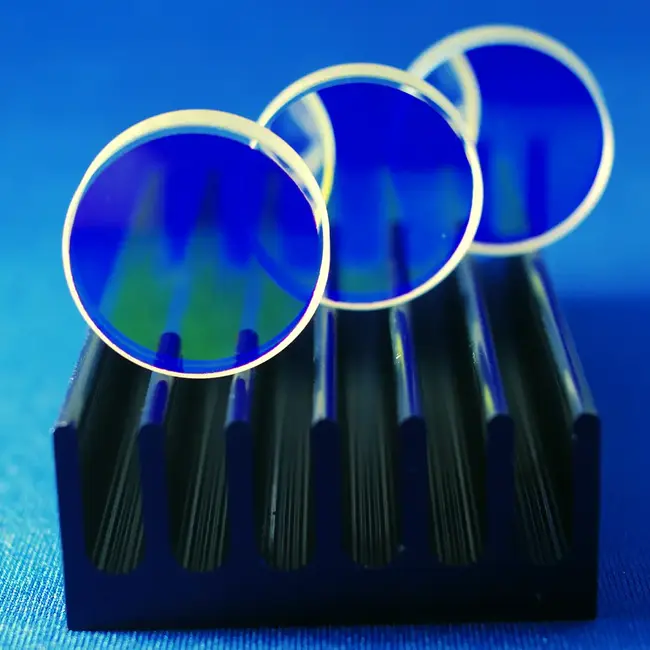

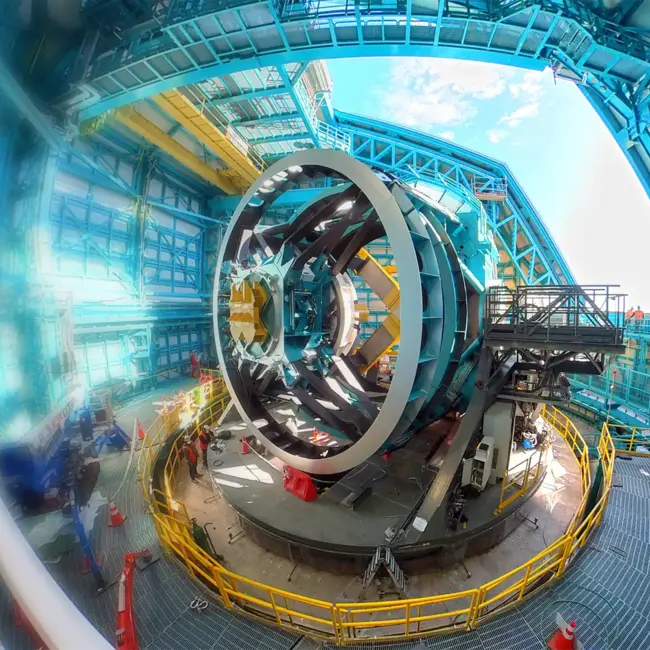

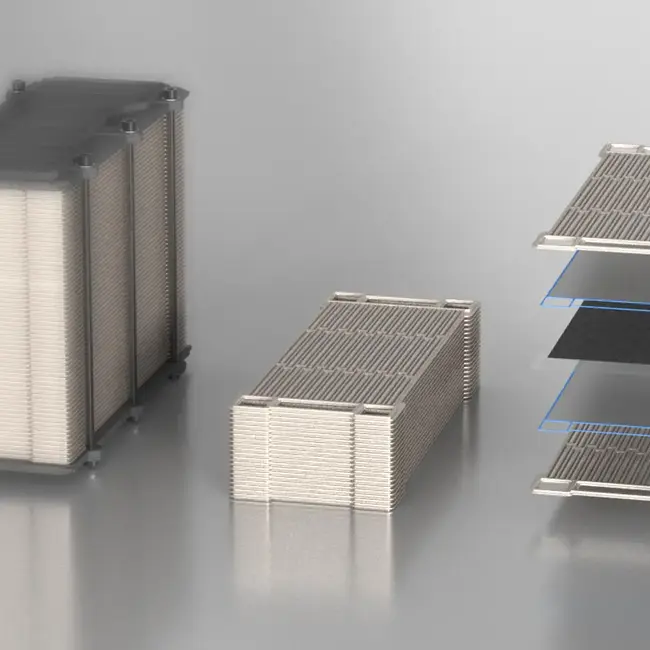

The highly productive VON ARDENNE systems for continuous sheet-to-sheet coating are used by manufacturers of architectural, automotive, or smart glass, in the photovoltaic industry, in the production of fuel cells, and in the display, semiconductor, and electronics industries as well as precision optics.

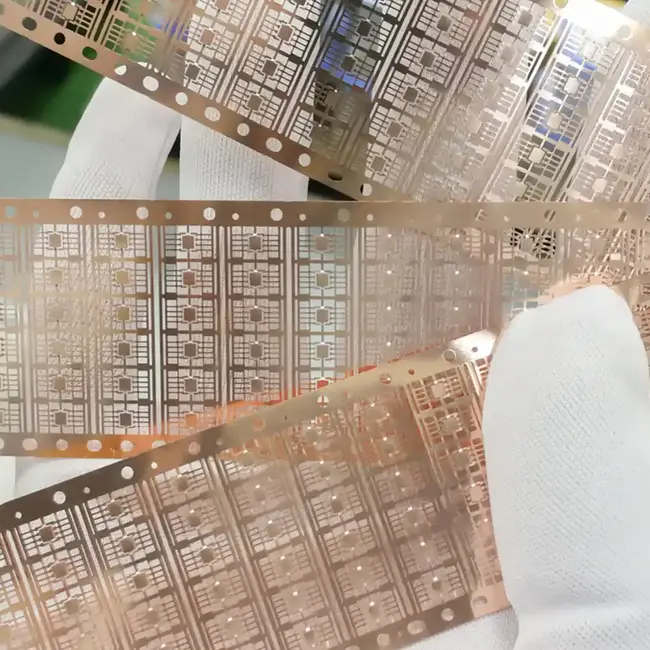

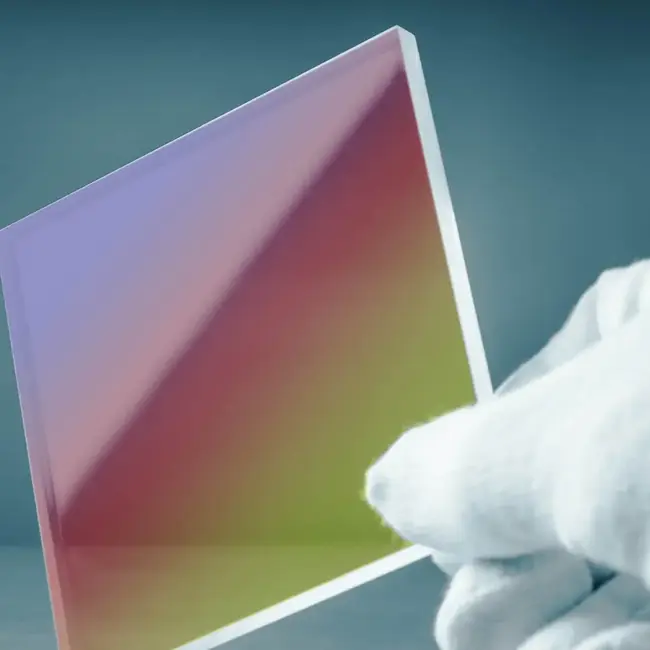

VON ARDENNE's decades of expertise in coating large-area architectural glass panes or thin-film PV modules now also benefits small and medium substrates such as wafers, metallic bipolar plates, or displays. Carriers with many slots for individual substrates ensure that these substrates can also be coated with the efficiency of volume production at the highest precision.

Depending on the application and available space, coating systems with horizontal or vertical substrate guidance as well as magnetron sputtering or linear evaporation are used as deposition methods.

For this purpose, VON ARDENNE offers technology expertise, process components, and plant systems from a single source. With extensive know-how from over 50 years of process development in magnetron sputtering and 60 years in electron beam technology, we support our customers in qualifying their products and processes.

We provide ideal conditions with our in-house sample coating systems and technological support for various substrate types and sizes – from initial laboratory tests to scaling up to mass production.

Would you like to learn more? Then click on the systems or take a look at the applications.

Applications

Engineering

Simulation . Sampling . Layout

Technology & Application Center

Sampling . Development . Scaling