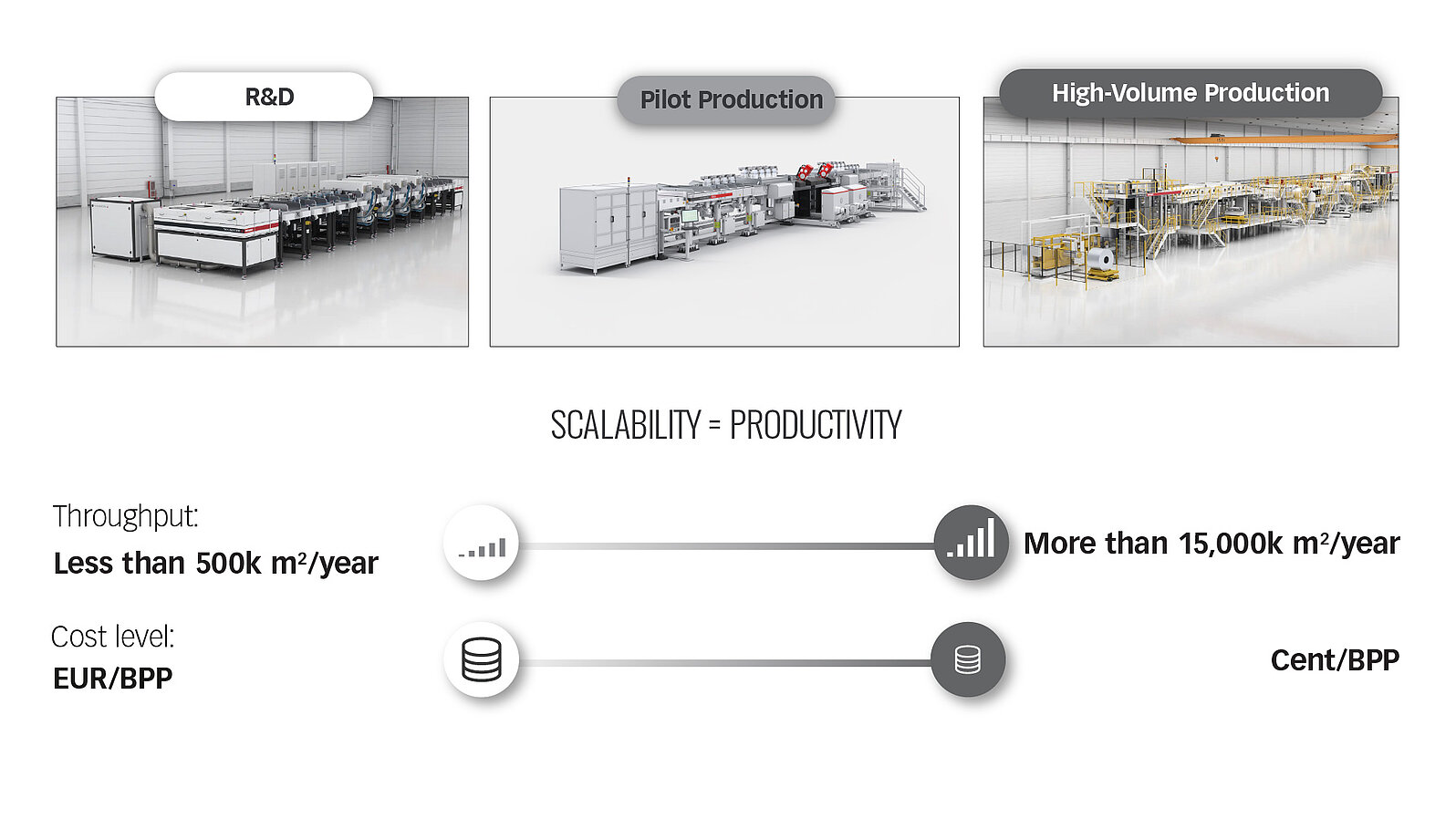

Scalable Equipment Solutions

We offer you ideal solutions for cost-efficient and highly productive manufacturing. They are tailored to your current and future requirements.

Our coating systems are based on modular platforms. This design will allow you to scale from research and development to high-voulume production.

Coatings for Metal Strip & Bipolar Plates

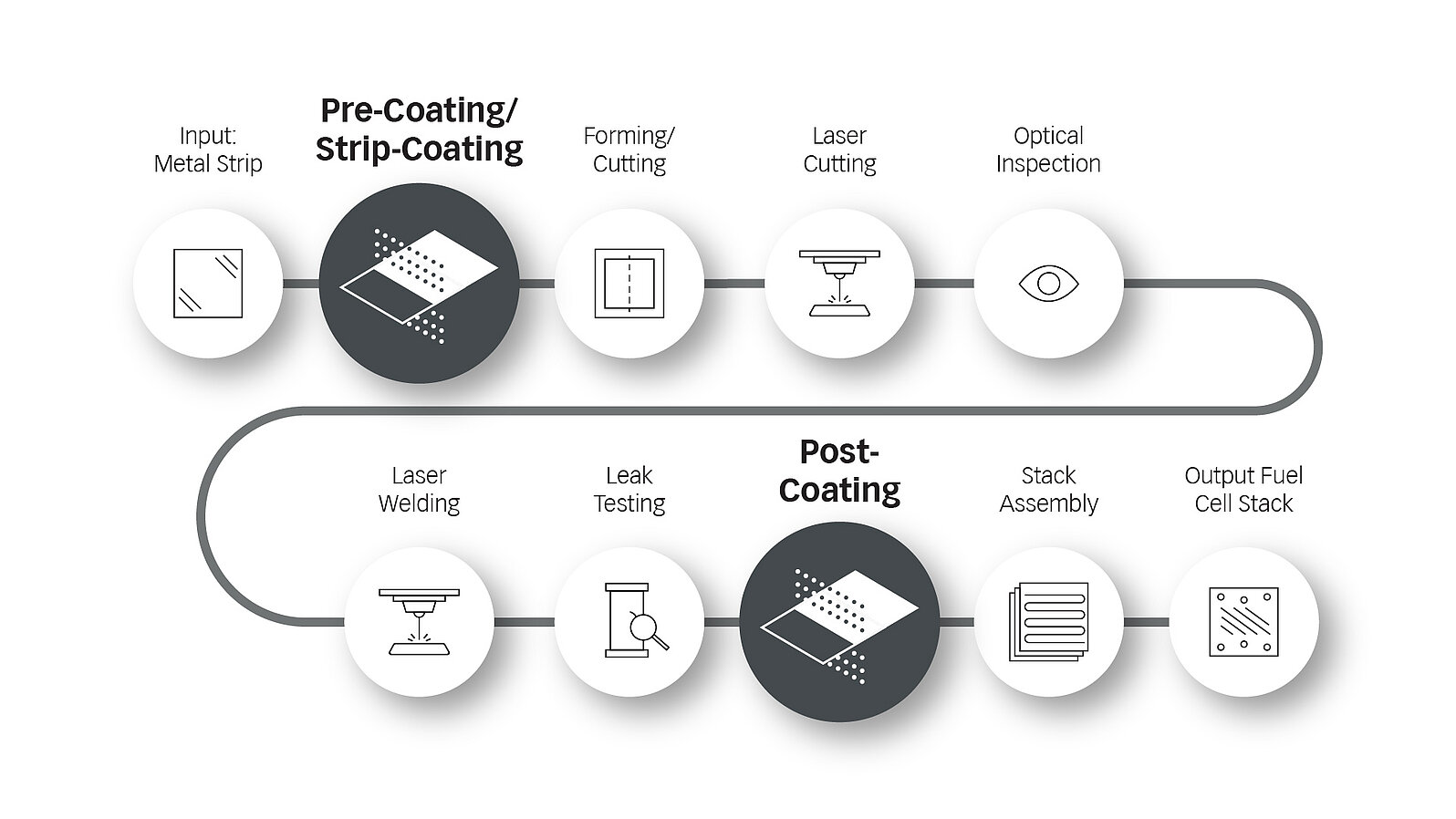

To offer you optimal pre- and post-coating solutions, we combine our equipment and PVD technology portfolio.

Pre-coating describes the coating of metal strip straight from the coil and focuses on high productivity at unrivaled low cost.

Post-coating, on the other hand, is a more conservative coating approach. Here, completely welded bipolar plates are coated on both outer surfaces while avoiding any interaction of the coating with the forming and welding process.

A third alternative is mid-coating, which means that anode and cathode halfplates are coated after the forming process but prior to their assembly into a bipolar plate.

Coatings for PEM fuel cells

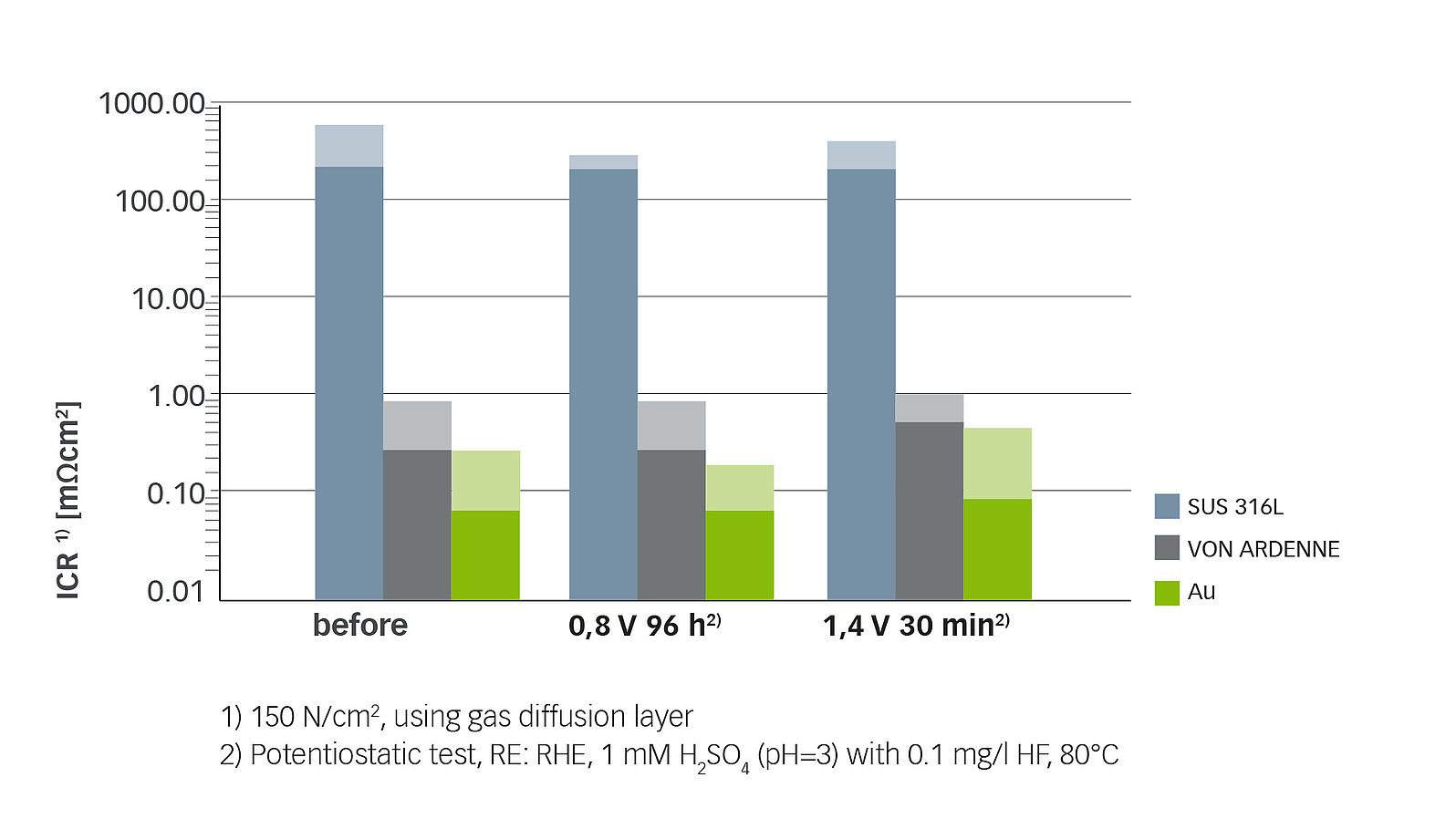

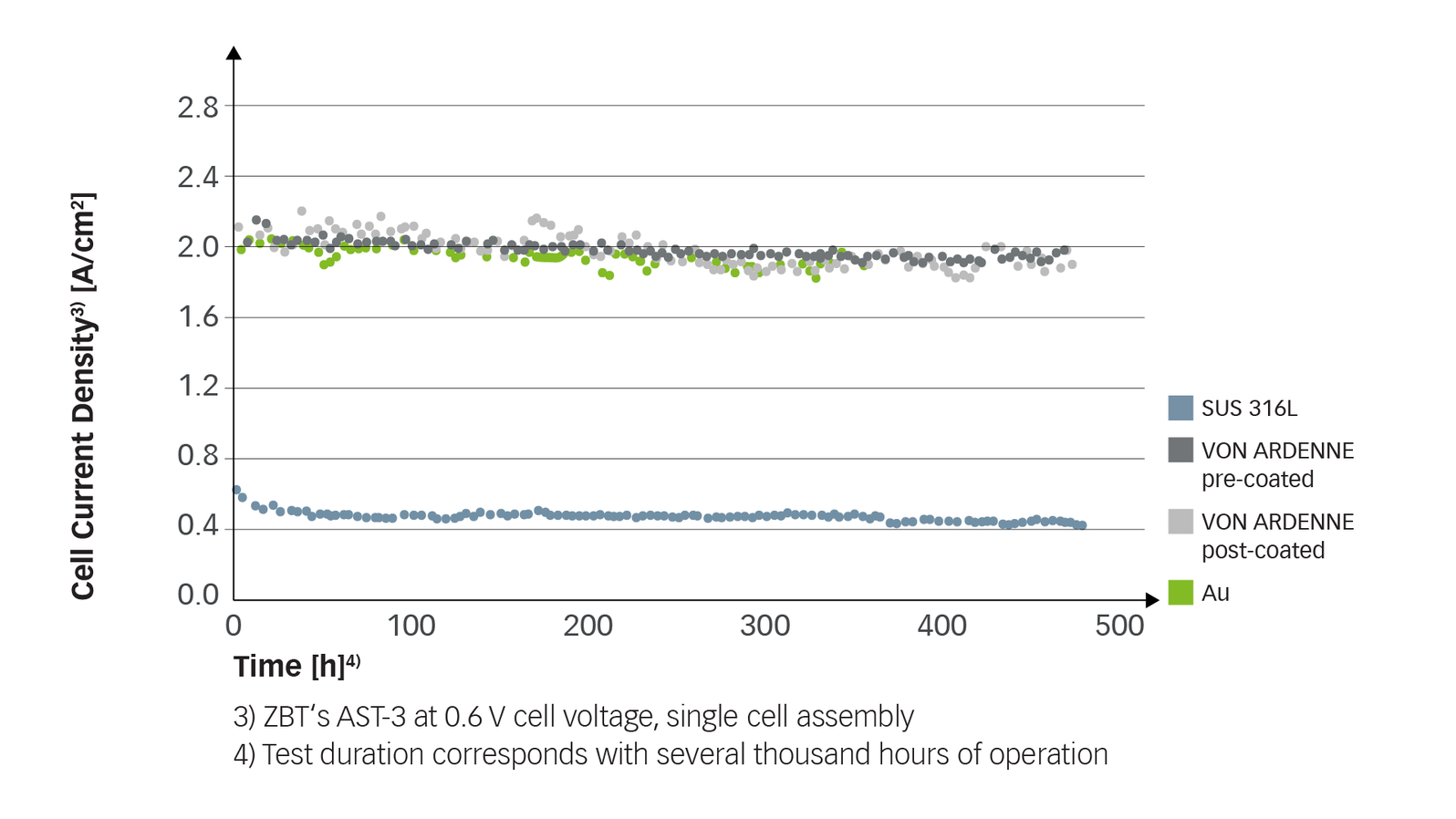

Our carbon-based layer stacks for PEM fuel cell applications are optimized for a low interfacial contact resistance (ICR), good adhesion and high corrosion resistance. The ICR, corrosion performance and durability of these layer stacks are comparable to the gold reference coating and have been qualified by renowned testing institutes.

Electrochemical corrosion test with Fraunhofer ISE

Accelerated stress test (AST) with ZBT

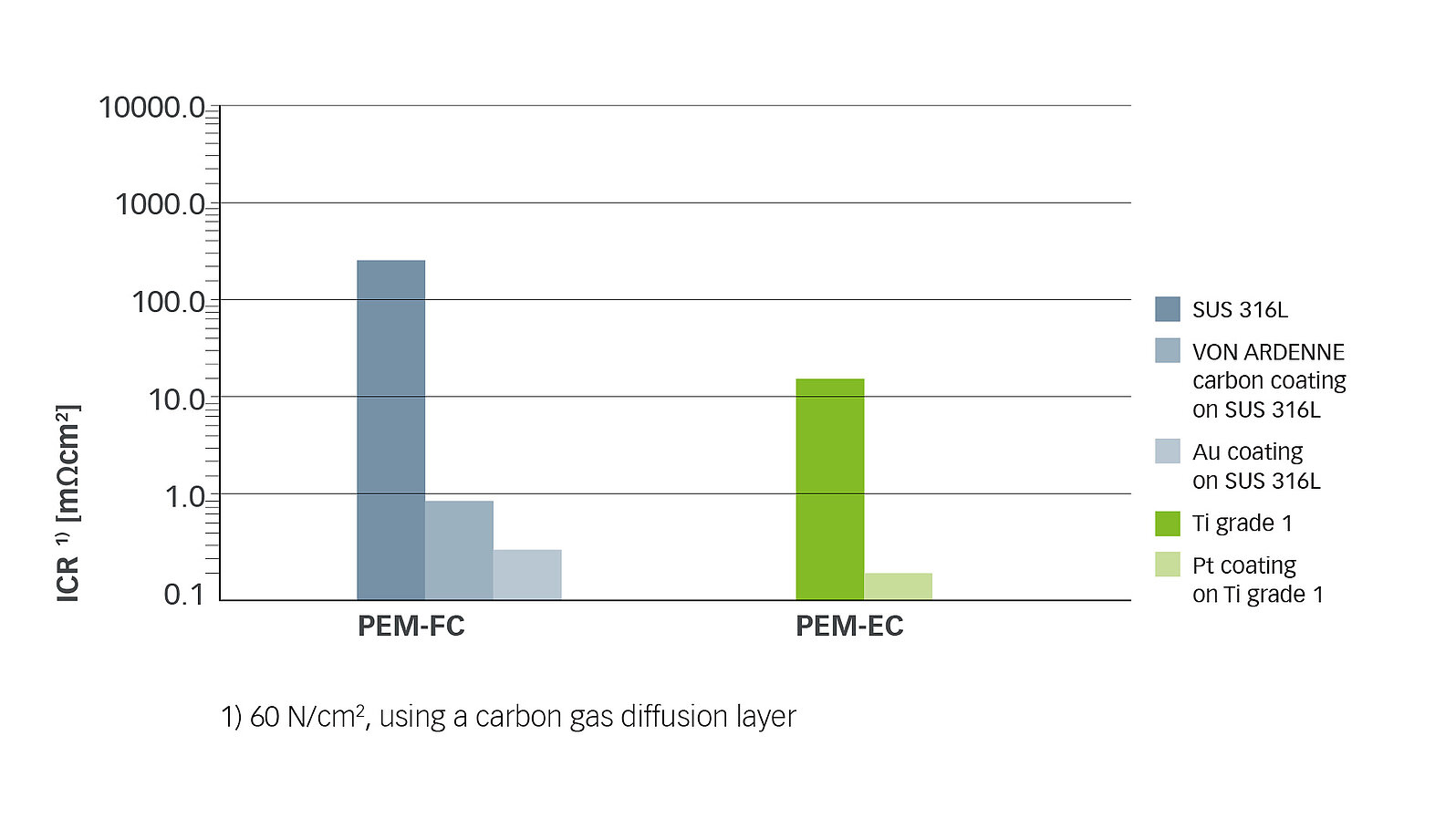

Coatings for PEM electrolyzers

VON ARDENNE also offers precious metal coatings for PEM electrolyzer applications. These coatings reduce interfacial contact / through-plane resistance (ICR/TPR) and provide corrosion protection at electrolysis anode potential.

Engineering

Simulation . Sampling . Layout

Technology & Application Center

Sampling . Development . Scaling

Service

Customer Portal . Spare Parts . Trainings

San Francisco, CA, USA

The Moscone Center

Booth 2261

Tokyo, Japan

Tokyo Big Sight

Shanghai, China

Shanghai New International Expo Center

N1 / 181

Orlando, FL, USA

Orange County Convention Center

Booth 1115

Shanghai, China

National Exhibition and Convention Center

A006